Manufacturing IT & AI Consulting

Proven IT Leaders with Track Records in the Manufacturing Industry

Manufacturing IT & AI Experts

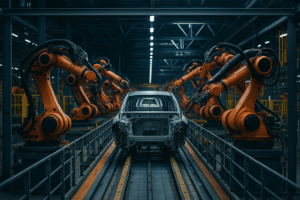

Manufacturing has always been a proving ground for innovation — from assembly lines and robotics to today’s AI-driven automation and smart factories. In this sector, technology is inseparable from production, supply chain management, and quality control, making IT a direct driver of efficiency and competitiveness.

Through our flagship Contract CIO+® tech leadership service and our foundational CIO IQ® IT & AI Advisory offering, Innovation Vista provides independent vendor-neutral IT & AI strategy to the Manufacturing industry. Our consultants combine technical expertise with real-world experience leading IT in automotive, electronics, industrial machinery, and consumer goods manufacturing. We know where general IT practices apply, and where manufacturing requires specialized strategies, such as IoT sensors for monitoring production, predictive maintenance for equipment, and analytics to optimize throughput and supply chains.

Unlike firms that drop in generalists, our experts have served as CIOs and technology leaders inside factories and manufacturing enterprises. With Contract CIO+®, the focus extends beyond stabilizing and optimizing IT platforms. It’s about ensuring technology improves yield, supports lean operations, and enables manufacturers to compete globally in a rapidly changing market.

Achievements for Manufacturing clients from our Consulting team

Our Manufacturing Scoreboard - Impact & Expertise

S.A. / Home Decor manufacturer

Led project portfolio across IT in preparation for the sale & integration of the company to a large competitor.

T.K. / Auto Manufacturer

As CIO for over a decade, led two rounds of modernization of the company's infrastructure, a cloud migration, and enterprise system selection.

State of Innovation in Manufacturing

Our 2026 Summary of Innovation in the Manufacturing industry

The Converged Floor & The Resilient Chain

Manufacturing in 2026 has moved beyond the pilot phase of Industry 4.0. The market now favors the “Resilient Enterprise”—manufacturers that use data to pivot production instantly and predict downtime before it occurs.

OT/IT Convergence is Complete: The air gap is gone. Operational Technology (machines) and Information Technology (business systems) are now a single network. While this drives efficiency, it has made the factory floor the #1 target for ransomware. “Zero Trust” segmentation is now a production requirement.

The “Digital Twin” Standard: We are no longer just monitoring machines; we are simulating them. Manufacturers use Digital Twins to stress-test production schedules and predict equipment failures weeks in advance, shifting maintenance from “reactive” to “prescriptive.”

The Augmented Worker (Industry 5.0): With the skilled labor gap persisting, technology is focusing on augmentation rather than just automation. AI-driven vision systems and AR (Augmented Reality) headsets guide newer workers through complex assembly tasks, reducing training time and error rates.

Supply Chain Control Towers: “Just-in-Time” has evolved into “Just-in-Case.” Manufacturers are deploying AI Control Towers that provide multi-tier visibility into suppliers, alerting procurement teams to geopolitical or weather disruptions instantly so they can secure alternative sourcing.

Interested in Leveraging Some of these Tech Capabilities? An Assessment Could Be Step 1.

Is your tech platform and organization ready to scale and advance? Many of our clients choose to start with an IT & AI Assessment and Recommendations report.

This is a high-leverage first step to gain actionable insights from our Manufacturing consulting team, validate your current IT and AI readiness, and discover how our expert collaboration can drive value for your organization’s future.

Manufacturing Leaders First - Then Tech Leaders

Our Unique "Top-line ROI" Approach to Manufacturing Technology

Many firms limit their work in manufacturing to Stabilizing IT platforms, tightening cybersecurity, and Optimizing infrastructure and costs. While these are necessary foundations, they don’t address the full scope of what manufacturers need — where downtime can halt production lines and even small inefficiencies can erode margins.

With Contract CIO+® and CIO IQ®, we align technology strategy with the realities of your operations. For a vehicle or electronics manufacturer, that may involve integrating ERP and MES systems for end-to-end visibility. For an industrial machinery producer, priorities might center on predictive maintenance, robotics, and IoT integration. For a consumer goods company, the focus could be on supply chain transparency and analytics that improve demand forecasting. Each manufacturing segment faces unique pressures, and IT strategy must reflect those specifics.

Where we create the most business impact is in Monetizing technology. We help clients Innovate Beyond Efficiency® by leveraging IT and data not only to cut costs but to generate top-line growth. That might include enabling real-time analytics that reduce waste, building digital platforms that enhance customer collaboration, or creating data-driven services that add value to your products. In manufacturing, technology is not just about efficiency — it’s a competitive weapon that shapes quality, delivery speed, and profitability.

IT Strategy for Your Manufacturing Niche

Manufacturing Sectors Covered

- FTC, OSHA, HACCP, EPA audit compliance

- Automobiles & vehicles

- Electronics & appliances

- Computers & IT hardware

- Furniture & housewares

- Industrial machinery

- Chemicals, Rubber, & Plastics

- Textiles & apparel

- Paper products

- Wood products

- Metal products

- Construction supplies

- Manufacturing automation & specialty software

Latest Manufacturing Tech !nsights from Our Team:

Analytics Maturity in Manufacturing · Analyzing our Mid-market Survey

Our CIOs with expertise in Manufacturing IT & AI consulting know that these companies generate enormous volumes of data through production lines, supply chains, quality control systems, and increasingly IoT-enabled equipment. Yet the sector is often constrained by legacy systems, long investment cycles, and complex operational environments. While stabilization and optimization are progressing rapidly, monetization is uneven. Some firms are turning predictive analytics and AI into revenue streams, while others are still struggling with foundational integration. The recent update to our Mid-market Analytics Maturity Survey provides a three-year view (2023–2025) of how Manufacturing companies are evolving across Data, Business Intelligence (BI), and Artificial Intelligence (AI). The results show near-universal stabilization and optimization by 2025, but wide variance in monetization across